Rollers

SICC S.L. is the exclusive distributor of Hob Certec ceramic rollers in Spain, Maghreb and Central America. Hob Certec, world leader in the production of ceramic rollers, produces a wide range of products for the different areas of the ceramic kiln, for the transport of all types of materials.

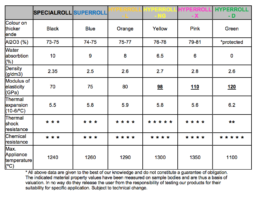

Ceramic rollers qualities:

Specialroll: The first roller designed by Hob Certec has demonstrated with its 20 years of life in more than 30 countries around the world a great reliability. Designed for the ceramic production of stoneware and porous in intermediate formats of weights and size.

Superroll: Second roller designed by Hob Certec, with 20 years of experience. Designed to support greater weights and with a higher modulus of elasticity than its competitors, this roller is an ideal choice in terms of quality- price.

Hyperroll-L: The first roller in the Hyperroll family, with the same composition as the Hyperroll NG, performs extremely well, at a more economical price. High modulus of elasticity and very good response to chemical attack.

Hyperroll-NG: Hob Certec´s best-selling roller for the ceramic production. Outstanding in modulus of elasticity and resistance to chemical attack. The Hyperroll NG is undoubtedly the best roller on the market for ceramic productions of standard formats. Especially suitable for porcelain materials.

Hyperroll X: Evolved roller of the Hyperroll NG offers a higher modulus of elasticity for extremely large and heavy materials. Maintains outstanding resistance to chemical attack. Especially suitable for XXL rollers and formats of more than 40 kilos per m2.

Hyperroll Dense: The only roller on the market with ZERO porosity, it has the highest modulus of elasticity on the market, thus being the most effective in transporting ceramic tiles without curvature. This roller gives its best results at the kiln entrance, up to 650ºC, where, thanks to its zero porosity, it withstands chemical attack extremely well.

Special products:

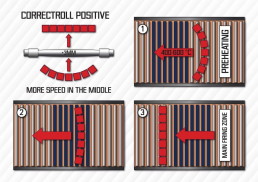

Positive correction rollers, allowing up to 3mm of positive correction diameter difference. Designed to align the ceramic tiles during the production process and thus substantially increase quality levels, avoiding blunting, twisting of pieces and snags.

Comparative table: